Industry

Metallurgy-Steel Factory

Loading: SG-650 4-roll reversible cold rolling mill

PWM four-quadrant rectifier power: 6150kW

Main mill power: 1900kW

Main mill speed: 403/1120r/min

Decoiler power: 250kW

Decoiler speed: 233/600r/min

Left and right winding: 2000kW

Rolling mill model: SY-22-B42

Rolling mill line speed: 600m/min

Rolling 6 mm thick steel plates into 0.18 mm sheets

The main drive motor pulls the strip through the gap between the rollers and presses the roll system through the downward hydraulic system, deforming the strip and making the exit strip thinner. The left and right uncoiling strip motors generate sufficiently extended stress/tension to pull the strip tight.

When the system is started, the uncoiling motor moves at a set tension driven by the main drive motor. To avoid "slack" or "breakage" of the strip, it is necessary to ensure that the line speed/second flow of the strip in the system is constant.

After each complete winding of the steel strip, the switch between winding and unwinding is made by an external switch, and so on until the strip is rolled to the target thickness.

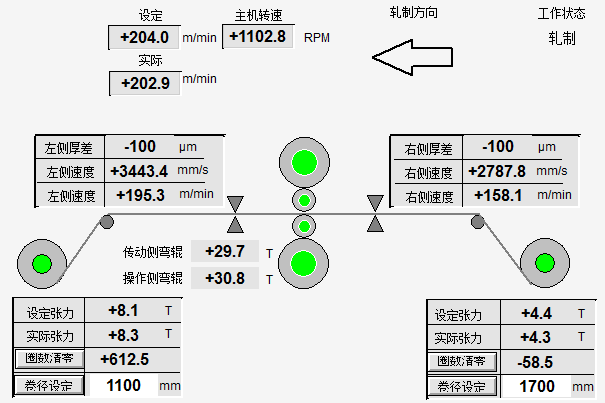

As show in the following diagram:

Situation in Site

There are three motors on site, one 750kW main drive motor and two sets of 450kW windings.

Input voltage: 690V

The rated frequency of the main drive motor is 27.8Hz and the maximum operating frequency is 76Hz.

The rated frequency of winding is 23.7Hz, and the maximum running frequency is 61Hz.

Tension control accuracy should be less than 0.5% and the maximum rolling line speed is 270m/min.

Solution

Common DC bus multi-drive EVFD inverter.

The rectifier adopts AFE active front-end rectifier unit (IGBT PWM rectifier), which has small current harmonics. It complies with IEEE519 standard and does not require additional harmonic filters.

The system configuration diagram is shown below.

Commissioning Result

In production process, 3.0*366mm steel was rolled into 0.344*366mm steel after 10 processes.

During the rolling process, NC EVFD series inverter controlled from high tension to low tension, from zero speed wandering to maximum speed running control, and from small load to large load rolling. The whole rolling process operated stably and fully, which met the demanding requirements of the site.

© Shanghai Nancal Electric Co., Ltd. 沪ICP备2021021924号