Metallurgy-Steel Factory

Shanghai Nancal Electric Co.,Ltd provides overall solution and project implementation of low voltage electric drive and automatic control system for 500-combination-forming single-stand reversible cold rolling mill.

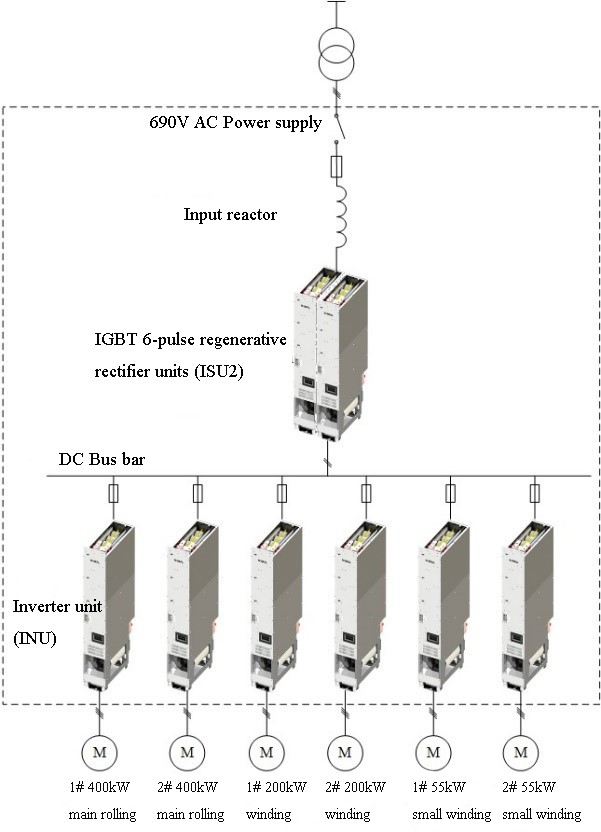

The project includes 8 machines, including 2 main rolling mills of 400 kW, 2 main winding/unwinding mills of 200 kW, 2 small winding/unwinding mills of 55 kW and 2 pressurized motors of 15 kW. all motors adopt NC EVFD series industrial drives. The input voltage of VFD is 690 V, the rated frequency of main mills and winding/unwinding mills is 30 Hz. The maximum working frequency is 90 Hz. The tension control accuracy is required to be less than 1%. The other drives adopt multiple drives with chopper brake module and braking resistor. The tension control accuracy is required to be less than 1%, and the maximum rolling speed is 200 m/min. 2 sets of 15 kW pressurized motors adopt single drive with chopper braking module and braking resistor, and other drives adopt multi-drive with common DC bus and IGBT six-pulse rectifier unit with regeneration function.

The overall control solution for reversible cold rolling mills is based on high-performance industrial microcomputers, programmable logic controllers (PLCs) and AC drive control systems. The latest all-digital system is used to form a fully distributed, networked, modern control system. An industrial field-bus is used for data communication between the drive control system and the automation control system. The operator console is designed according to the principles of sophistication, centralization and convenience.

© Shanghai Nancal Electric Co., Ltd. 沪ICP备2021021924号